Valley Precision featured in The Fabricator Magazine

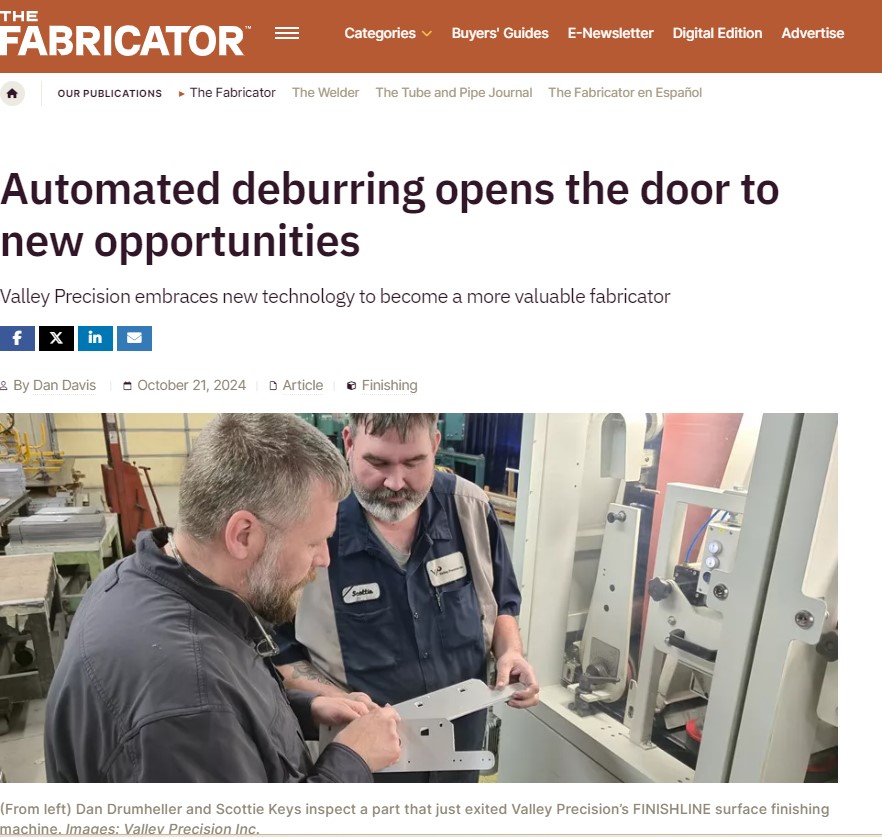

Valley Precision featured in The Fabricator Magazine! Valley Precision had an opportunity to be interviewed and have a nice article written by Dan Davis from the Fabricator Magazine. This is one of the most popular magazines in the fabrication industry, and is a leader in the industry news. We are so grateful for this wonderful article, the nice writing, and the pictures. Thank you Dan Davis, and Jeff Desper, and Scottie Keys, for making this article possible.

Valley Precision and Atlantic Union Bank

Valley Precision was featured as a client success story by Atlantic Union Bank, and also we got to appear in an ad in “Virginia Business Magazine” which is really a nice thing! I’m so proud of the people at Valley Precision Inc. and all they have done to make this business a success.

New HAAS VF4SS added to Valley Precision

Recently, Valley Precision added a new milling machine to our arsenal! We purchased a HAAS VF4SS with 4th axis rotary, and it arrived a few weeks ago and is already making parts for our customers. This machine has high-speed machining, wireless probing system, and all of the options we need! Please send us your CAD solid models to quote, and let us make your parts on this nice new machine! We are so thankful for the opportunity to keep upgrading our equipment and facilities at Valley Precision. Dan D

Finish Line Sander / Brush Finishing added to Valley Precision

In order to make even higher quality sheet metal items with beautiful finishes, we have added a Finish Line Sanding Machine which deburrs and applies a brush finish to your items. This machine is capable of applying finishes to parts up to 43″ wide, of any length. Check out the video of Scottie Keys running this machine. Scottie is very skilled with sheet metal fabrication, laser cutting, punching, forming, and finishing. He can set up and operate all of our sheet metal fabrication equipment at Valley Precision. We are glad to have nice new equipment and skilled people like Scottie Keys at Valley Precision!

LVD Lynx 4kw Fiber Laser added at Valley Precision

Valley Precision installed a newLVD Lynx 4kw Fiber Laser cutting machine recently to add to our sheet metal cutting arsenal. This machine cuts stainless steel, aluminum, and steel, with speeds as fast as 1500 inches per minute on thin materials, and can cut up to 1″ thick steel. Valley Precision continues to add and upgrade our machines and offerings to produce high-quality parts for it’s customers. We are fortunate to have smart Engineers, operators, quality control managers, and workers of all types that care about producing wonderful parts! See video of this machine operating here LVD LYNX FIBER LASER CUTTING

Aluminum Machining

Aluminum Machining By Dan Drumheller Today we are machining some nice aluminum heatsinks at Valley Precision. The pattern that the carbide-tipped cutter makes is really nice. This shows good surface finish and machining technique programmed by Jason Linke. We are very pleased to have Jason at Valley Precision doing such good work. It’s amazing to watch the things that he can create.

HAAS VF3SS added to Valley Precision

Recently we added a nice upgrade to our machine shop with a HAAS VF3SS vertical milling machine. This machine is fast, accurate, and is skillfully operated by our expert machinists. We are so fortunate to have good equipment and employees. Send us your machining work and we will run your parts on our new machine! We also have a variety of other HAAS and other CNC milling machines that are available and fast! This is the newest of six vertical machining centers at Valley Precision.

Valley Precision adds new equipment

Valley Precision has recently added two lasers to our arsenal of sheet metal cutting capabilities. Last year, we added a 4kw CO2 laser by LVD to our shop. After seeing the productivity increase with that machine, we added another 4KW Lynx Fiber laser by LVD to our shop as well. At this time we are running 10 hours per day on two lasers, and one punch press. Adding the lasers was necessary and so productive! The results are amazing. Our shop can handle a wide variety of sheet metal cutting needs, and our throughput has doubled in the past year. Wow!

State of the art Programming Team

Recently we have been training a new employee. He came to visit us on his birthday, and we thought he would be a good candidate for our programming requirements. He is learning quickly. It’s astonishing to watch someone so young, adapt to technology so quickly. He has been programming the laser to cut out racecars, dogs, and pictures of candy and other treats. By the time he graduates high school he should have 15 years of experience. We are glad to be contributing to the efforts of youth to be part of the manufacturing community! Eli is a prodigy, and we are excided to follow him as he grows in his career. Thank you to Daniel Poole for bringing Eli in for a visit on his birthday!

Sheet Metal Enclosures

Sheet Metal Enclosures Today I was walking through the shop and happened across this common sight here at Valley Precision. Stacks and stacks of metal enclosures that are punched, deburred, formed, welded, fasteners inserted, and ready to ship! There is something satisfying about seeing multiples of the same product stacked neatly in a row. Stacking products neatly also offers a quick way to glance at each part and make sure they are all the same, have the same fasteners, and are exactly alike. Consistency, repeatability and quality go hand-in-hand at Valley Precision. If you have parts like this that need to be manufactured, by all means get in touch with us! Dan D